When refrigeration is the key to keeping your products fresh and your business running smoothly, prefabricated cold rooms are a lifesaver. No matter whether you are a small snack shop or run a massive scale food production, having a prebuilt cold room can bring all the difference. They are not only affordable and convenient, but a necessity of any food based business. Nonetheless, like any machinery, prefabricated cold rooms can encounter common problems. Understanding how to solve these problems is essential if you want your cold storage to work and last. That is where working with the top prefabricated cold room supplier in Changzhou – New Star Refrigeration Co., Ltd. – can prove to be all the more useful. We’ve broken down their cost effectiveness, what makes them fast and efficient to install for commercial operations, what they offer in terms of the value for money as investment, and how prefabricated cold rooms are a necessity for food businesses including common problems one could experience and solving with an industry leader such as New Star.

Prefabricated cold rooms benefit businesses of all sizes. Some of the benefits are obvious, from convenience to higher productivity. One of its good side is very easy to install. Prefabricated cold rooms And as opposed to traditional cold storage options, a prefabricated room can be assembled fast so that you won’t have to wait long in between downtime before using it. Moreover, prefab cold room is custom depending on your detailed requirements. Whether you are looking for a small walk-in freezer or a big cold storage facility, the prefabricated cold room can be manufactured and designed according to your own requirements. There is also a much more functional aspect and that's saving energy. Such prefabricated cold rooms specifically are engineered to feature maximum thermal efficiencies, so you can cut down on your utility bills in the long run. This not only is good for your bottom line, but it also helps to minimize your environmental impact. Given these advantages, it's no wonder that a prefabricated cold room is a wise business investment.

There are two reasons why prefabricated cold rooms are higher regarded than traditional cold storage solutions – affordability and efficiency. Ready made cold room are affordable solutions and is called as domestic chiller. There is a variety of sizes and system types to choose from enabling you to select the cold room size that suits your budget without compromising on quality. What's more, prefabricated cold rooms are renowned for being energy efficient so you save money on running bills in the long run. With a pre-made cold room, you can save much time, money and your products. This blend of cost-effectiveness and effectiveness make prefabricated cold rooms the perfect option for companies in need of an affordable cold storage solution that won’t entirely blow out the budget.

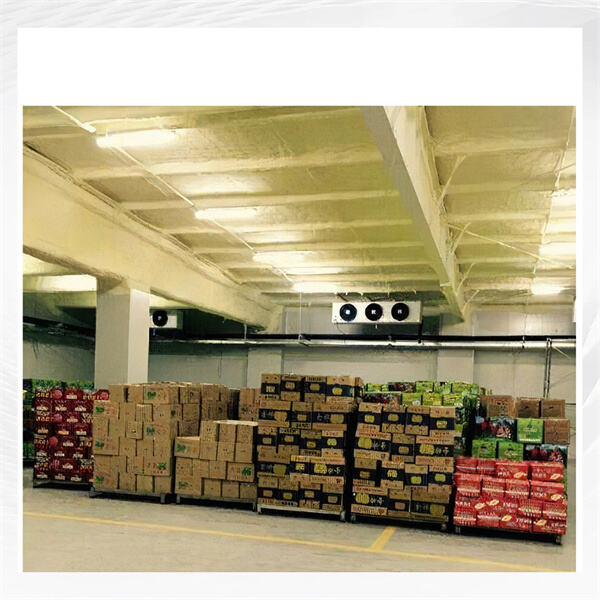

The food industry demands the quality and freshness of products. It’s no wonder that proper storage solutions such as pre built cold rooms are part of a non-negotiable criteria for businesses involving food. Whether you are a restaurant, café or food processing facility, we know that having a dependable cold storage system is critical for your products to be safe and of the highest quality. Temperature controlled with the most accuracy Prefabricated cold rooms provide precise temperature control and maintain the ideal conditions - retaining your products in perfect condition. This not only prolongs the shelf life of your goods, it also saves you from food waste. Moreover ready-made cold rooms are tailored to the needs of customers as they need their products in a clean and secure conditions. And as we all know, the food industry is extremely competitive.If you've been keeping up with the latest trends in the commercial event catering sector - then you know that a prefabricated cold room is now one of the lynchpins to staying ahead in business & supplying your customers with produce at its freshest.

Prebuilt cooler rooms have a lot of pros, but they may look for still suffer from problems. One frequent challenge is uneven heating and cooling, resulting in spoilage or product waste. To resolve this problem, it is essential to monitor and optimize the temperature controls frequently and be sure sufficient airflow enters the cold room. Yet another potential problem can be leaks in door seals which will effect the seal tightness of the cold storage. Leaking shut of a cold room is a sign that the quality or level of your door seals need to be replaced; routine check and replacement where necessary can ensure no such leaks are present in your cold room. Also, condensation collection is a second problem that may promote mold growth and equipment damage. In order to avoid this, it is important to ventilate the cold room properly and deal with any source of moisture in a timely manner. By being proactive and tackling these regular issues as they occur you can keep your prefab cold room going strong.